AIR SEPARATOR FOR CLEANING COAL YouTube

#0183;#32;AIR SEPARATOR FOR CLEANING COAL YanFeng Shi. Loading Coal Cleaning Shaker Box Duration: Fisher Industries 4,721 views. 2:00. UMS Air Jig CORE Machine Duration: 0:38. UMS

WhatsApp)

WhatsApp)

#0183;#32;AIR SEPARATOR FOR CLEANING COAL YanFeng Shi. Loading Coal Cleaning Shaker Box Duration: Fisher Industries 4,721 views. 2:00. UMS Air Jig CORE Machine Duration: 0:38. UMS

In this study, 4 mm coal fines from Soma region of Turkey with the ash content of 3132 % were treated through air jig employing the pulsation effect and the aerodynamic separators which

#0183;#32;Coal washing Coal that comes from a mine is a complex mixture of materials with a large variety of physical properties. In addition to the coal itself, pieces of rock, sand, and various minerals are contained in the mixture. Thus, before coal can be sold to consumers, it must be cleaned. The cleaning process consists of a number of steps that results in a product that is specifically suited to

Dry coal cleaning techniques can be divided into three groups; air table, air jig and dry dense medium separator. Air table and air jigs were used to clean the coal. However, by 1985 the coal processing using these methods dramatically dropped to less than 7 million tons per year [5].

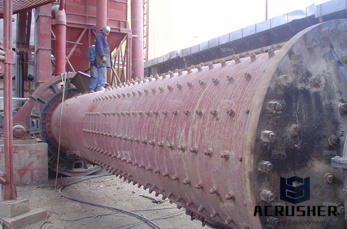

Air Jig For Separation Of Minerals From Coal. As a global leading manufacturer of products and services for the mining industry, our company can provide you with advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan.

July 6, 2018 Zambia Mines Rescue Bus Handover; January 9, 2019 MINING COMPANIES ACCOUNTED FOR MORE THAN A QUARTER OF GOVERNMENTS INCOME ZAMBIA EITI REPORT.

AllAir Jig: DensityBased Separation The AllAir Jig is a unit modified from the Stomp Jig. Coal is fluidized by a constant flow of air across a perforated table. Pulsating air provides the jigging action. Nuclear density gauge used to assist the control of reject rate. Units up to 100 tph are available. Raw Coal Pulsed Air Flow Constant Air

AIR JIG. The Pneumatic process of beneficiation is the best suited option for Coals which has very high percentage of Near Gravity Material. This method involves size reduction and screening of coal to segregate it into defined sizes followed by concentration separation of particles into fractions more homogeneous in nature.

Jigging is an ancient but mature coal washing technology by gravity. It has more than 110 years history since the application of air jigging machine. However, because the theoretical research of jigging coal washing technology is still wandering at the hypothesis stage, it also seriously relies on operators experience and skill, which results into no publicly recognized and uniform jigging

Originally developed and patented in 1919, the density separation is achieved with two components, mechanical vibration and air fluidization. Today, Triple/S line of density separators and stoners are being used in thousands of applications, from cleaning of leafy spices and peppercorns to reclaiming copper from scrap wire and cable.

coal was introduced in 1916. By 1938, air separators accounted for 16 percent of the clean coal produced in the United States. Historically, the coal industry preferred air jigs to other dry separating devices. This is where the development of Allminerals air jig (Allair Jig) began. Because there had been no advances in air jig technology for

Air jig cleaning of coal in china romanticliving coal washing there are two coal cleaning processes that predominate in the industry dense medium dm separation and jig washing jig washing, which is a waterbased process that relies on the pulsation of water through the particle bed to stratify particles of different density, is widely.

The cleaning of coal by the use of jigs is one of the oldest methods of separating coal from its impurities. Although in many situations jigs have been replaced by other methods, by far the largest percentage of coal today is still being cleaned by some form of jigs. Description of the Batac Jig In the Batac, the pneumatically pulsated principles of the Baum jig are still used; however, the

An air jig can remove much of the rock in the raw coal with little product loss, thereby reducing transport cost, processing costs and the cost of reject disposal at the central washery. The air jig is best suited for separations of specific gravity and higher.

A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

Cleaning in Zambia. List of Best Cleaning Services in Zambia, Top Cleaning Services in Zambia, Cleaning Services Near Me, Best Cleaning Services.

Coal continues to play a major role in the economic development of India, especially in conventional power generation plants. The wet beneficiation process for coal cleaning is currently the predominant method of purification of coal in the world. However, dry beneficiation of coal has obvious advantages over wet processes.

WhatsApp)

WhatsApp)