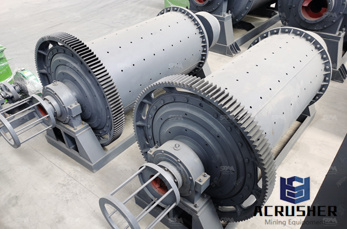

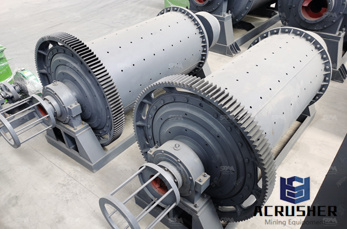

Ball Mill For Ink Manufacturing

ball mill for ink manufacturing CMS (Crusher Machine wall puty ball mill machine manufacturers address youtube . 22 may 2014 wall putty machine tipco engineering works the machine is used in paint, dyes and ink

WhatsApp)

WhatsApp)

ball mill for ink manufacturing CMS (Crusher Machine wall puty ball mill machine manufacturers address youtube . 22 may 2014 wall putty machine tipco engineering works the machine is used in paint, dyes and ink

73,478 ball mill products are offered for sale by suppliers on, of which mine mill accounts for 25%, grinding equipment accounts for 5%, and flour mill accounts for 1%. A wide variety of ball mill options are available to you, There are 73,500 suppliers who sells ball mill on

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50 % of the mill volume and its size depends on the feed and mill size.

Three Roll Mill Related Articles, Mixing Technology Insights and Whitepapers. Best practices for safe and efficient three roll milling. Create smooth, speckfree pastes in your Three Roll Mill. Upgrade your ball mill process by switching to a three roll mill.

Manufacturer of Resin Manufacturing Plant, Ball Mill amp; Sand Mill offered by Raymer Engineering Corporation from Mumbai, Marashtra, India. Raymer Engineering Corporation. Mazgaon, Mumbai, Marashtra. GST No. 27AAAPE0279K1ZT. TrustSEAL Verified. Call 80% Response Rate. SEND EMAIL.

I have some lump charcoal that just came out of my retort after I cooked it, and I want to turn it into airfloat charcoal. Or, the directions say to ball mill my rocket fuel for an hour. An article tells me to ball mill my star composition prior to pressing my stars. Maybe I just got some crystal...

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill amp; ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment. In present day practice, ore is

Ink Manufacturing and the Dispersion of Three Roll Mill. Ink Manufacturing and the Dispersion of Pigment into Ink 1. Introduction Ball mill Medium shear Not needed Used in the bead form of it is widely accepted to employ the three roll mill to process the ink composition by the provided high shear force.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming

Certain more difficult to mill pigments may need to be passed through the mill an additional time. The three passes follow on from each other with increasing pressure between the cylinders that perform the milling: the first milling stage, which fines down the premixed ink, the second milling stage, which breaks up any remaining agglomerates and the final milling stage, which completes the

Ball mills, along with grinding mills, impact crushers and a variety of other equipment, are used for the reduction of all kinds of materials for all kinds of purposes. Size reduction is an important part of many industrial processes, making ball mills and other pulverizing mechanisms vital to

ink involves four major steps: preassembly and premix, pigment grinding/milling, product finishing/blending, and product filling/packaging. Some of the equipment used to accomplish these manufacturing steps include roller mills; ball and pebble mills; attritors; sand, bead, and shot mills; horizontal media mills; and highspeed disk dispersers.

Basket Mill For Ceramic Ink. The ceramic ink basket mill is a wet grinding machine which integrate dispersing and grinding together. Products Details 1Temperature sensors for inlet and outlet cooling water and for products...

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Ink manufacturing process can be described as a mixing process. Pigments, binder and additives are usually separately synthesized beforehand. An important task in this process is pigment dispersion. To break up pigment agglomerates, three roll mill, ball mill, and other type of mills might be employed.

Ball Mills Steel Ball Mills amp; Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

WhatsApp)

WhatsApp)