Handbook Of Conveyor Belt Design...pdf

Conveyor Belt Design Manual Bridgestone1 Free download as PDF File (.pdf), Text file (.txt) or read online for free. Read more Phoenix Conveyor Belts Design Fundamentals

WhatsApp)

WhatsApp)

Conveyor Belt Design Manual Bridgestone1 Free download as PDF File (.pdf), Text file (.txt) or read online for free. Read more Phoenix Conveyor Belts Design Fundamentals

Oil resistance: we supply conveyor belt for the pulp and paper/wood industry as well as the grain industry. Flame resistance: these compounds consist of MSHA approved belts for aboveground prep plant and power plant applications, aboveground mining.

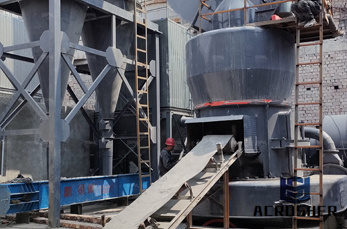

Belt Conveyor PDF Download. What is Belt Conveyor. Belt conveyor is also called conveyor belt, which is a kind of transport machinery driven by friction and can transport materials in a continuous conveyor is also an economic conveying equipment of logistics and has become an indispensable for assembly line operation.

Conveyor Belt Design. Conveyor belts are critical to transporting bulk materials throughout a process or facility. Good conveyor belt design is important to ensure conveyors are reliable and can be safely maintained and operated. A well designed and properly installed conveyor increases productivity.

#0183;#32;Belt conveyor designdunlop 1. CONVEYOR BELT TECHNIQUE D E S I G N A N D C A L C U L AT I O N 2. I Index 1 Introduction Foreword Development chronology, development aims DunlopEnerka test rig 2 Belt Conveyors Basic sketch, concept, description 3.

Troughed belt conveyors are used prolifically throughout the mining industry, carrying ores, concentrates, and tailings throughout every stage of the mining cycle, from initial excavation, through beneficiation, to the production of a refined material ready for market, and each step in between. Belt conveyors are customized and combined in an

MIPR Corp engineers can also customize each conveyor belt to match a particular mining material, production requirements, or conveyor system design. This can range from custom cleating to stitching multiple belts together to create wider surfaces to adding diverters, photo eyes, and more.

Conveyor Accessories. From our innovative designs to our quality materials and outstanding service, see why Conveyor Accessories gives you the edge. To make installation of our belt fasteners as easy and effective as possible, we have developed proprietary tools designed specifically to

IMPROVEMENTS IN CONVEYOR BELT FIRE SUPPRESSION SYSTEMS FOR COAL MINES Kara A. Teacoach, NIOSH, Pittsburgh, PA, USA James H. Rowland, NIOSH, Pittsburgh, PA, USA Alex C. Smith, NIOSH, Pittsburgh, PA, USA many mines with multiple mining sections have gone to main line belts of m width and some are even .

Phoenix Conveyor Belt Systems produces heavy weight conveyor belt for mining locations and a variety of industries around the world. Our expertise and experience has produced significant advancements in conveyor belt design, including world records for the strongest belt (both textile and steel cord), the steepest overland and worlds heaviest belt.

#0183;#32;Smart conveyor belt design. A smart way to design conveyor belts as per DIN 22101 (2002 or 2011 issues) employing dynamic splice efficiency, is reducing the belt rating and bringing down overall costs. It is described in a paper called quot;Stateoftheart long distance conveyor belt designquot; published in Coal Asia Magazine.

MIPR Corp engineers can also customize each conveyor belt to match a particular mining material, production requirements, or conveyor system design. This can range from custom cleating to stitching multiple belts together to create wider surfaces to

#0183;#32;Development of Conveyor Belts Design for Reducing Energy Consumption in Mining Applications. June 2016; DOI: / based on common inputs applied in the mining

From design analysis, the speed of the pulverizer shaft, belt velocity, maximum belt tension and power transmitted by the pulverizer belt were 900 rpm, m/s, N and W respectively.

Tunnel conveyor PC 2. With 16,820 m pulley center distance and 471 m lift this conveyor is still one of the largest conveyors worldwide. With the task to design an energy efficient system with reduced capital costs for belting and drives several investigations were made.

Belt conveyor systems continuously transport all forms of material, including excavated and crushed rock, in an efficient manner due to their effective availability. They cover a wide range of applications, from mining or extraction to inplant or overland where they convey material over long distances, passing through curves and rough relief areas.

WhatsApp)

WhatsApp)