How To Make Manual Clay Bricks Classical Complete

#0183;#32;How To Make Manual Clay Bricks Process In India amp; Pakistan Fire Brick Kiln Industry Documentary bricks are one of the longestlasting and stronges...

WhatsApp)

WhatsApp)

#0183;#32;How To Make Manual Clay Bricks Process In India amp; Pakistan Fire Brick Kiln Industry Documentary bricks are one of the longestlasting and stronges...

offers 2,145 clay brick making machine production line in india products. such as free samples.

#0183;#32;We supply complete set of automatic red brick production line, including solid and hollow clay bricks making machines, automatic bricks stacking machine, tunnel kiln

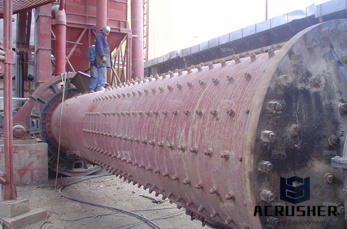

The core part of clay brick production line is the vacuum brick making machine which can make two kinds bricks, solid clay brick and perforated brick by using different mold. Without drying, the clay bricks are grab by the robot hand automatically onto the tunnel kiln car, and enter into the tunnel kiln for firing and then shipped by professional kiln car out of the kiln, for stacking for sell.

Neptune Industries Ltd. is a Joint venture company between Alpina Industriale SpA Italy and Neptune Industries Ltd, India for the manufacturing amp; Supply of Red Clay Brick/ Block making plant and Autoclaved Aerated Concrete Block making plant (AAC) Automatic Red Clay Brick . Capacity range : 25,000 to 3,00,000 Brick/ Block per day OR. Capacity range: 100 to 900 Ton per Day

Buyers can get Million Clay Brick Production Line (2030) designed and executed by us within their stipulated budget and deadline. We have a team of highly qualified engineers to design and assemble an optimally functioning, high performance and reliable Million Clay Brick Production Line (2030) and provide excellent after sales support as well.

Find here Clay Brick manufacturers amp; OEM manufacturers India. Get Contact details amp; address of companies manufacturing and supplying Clay Brick across India.

Buyers can get Million Clay Brick Production Line (2030) designed and executed by us within their stipulated budget and deadline. We have a team of highly qualified engineers to design and assemble an optimally functioning, high performance and reliable Million Clay Brick Production Line (2030) and provide excellent after sales support as well.

Clay brick making business plays good role in India economic development and it tends to make enormous efforts to Indias financial activity. And clay brick has wide distribution in India and it is actually a vital stone for stone functioning and architecture. The organic clay brick from India is broadly made use of as clay brick tiles, clay

India. The following steps are involved in the clay brick manufacturing: 1. i) Material procurement : In Assam the basic raw material is Alluvial clay with requisite plastic properties. The requirement for 1000 clay bricks is as follows: Clay : 4 tones Silt : tones Coal : tones Water : 34 Kl

Wangda Red Clay Bricks Making Production Line Came into Use in India. Wangda have built a high yield tunnel kiln in India, and our whole red clay bricks making production line machines have been came into smoothly use! Wangda Machinery is a powerful brick machine manufacturing center in China.

clay brick production line manufacturer/supplier, China clay brick production line manufacturer amp; factory list, find qualified Chinese clay brick production line manufacturers, suppliers, factories, exporters amp; wholesalers quickly on

Designed for an Annual Output of 2030 Million Clay Brick Production Line | High Capacity Clay Brick Machines | Wangda India wangdaindia, info Enquire Now

Designed for an Annual Output of 2030 Million Clay Brick Production Line | High Capacity Clay Brick Machines | Wangda India wangdaindia, info Enquire Now

Yingfeng JZ300 soild clay brick produciton machine in India. Yingfeng JZ300 solid clay brick produciton machine to India. it is nonvacuum brick production line .Capacity is 4000 bricks per hour for india brick ( 230X105X77mm) . For more information welcome to visit our website:

Then the clay or shale mixtures are transported to plant storage areas (see Photo 1). Continuous brick production regardless of weather conditions is ensured by storing sufficient quantities of raw materials required for many days of plant operation. Normally, several storage areas (one for each source) are used to facilitate blending of the clays.

WhatsApp)

WhatsApp)