(PDF) Acoustic emissions monitoring of SAG mill performance

#0183;#32;Surface vibration (acoustic emissions) monitoring is a noninvasive lowcost means of monitoring normally inaccessible attributes of processes or

WhatsApp)

WhatsApp)

#0183;#32;Surface vibration (acoustic emissions) monitoring is a noninvasive lowcost means of monitoring normally inaccessible attributes of processes or

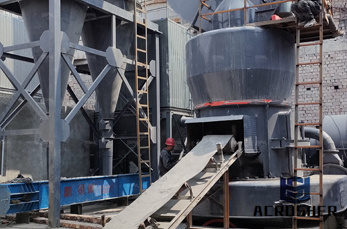

Condition Monitoring of Ball Mill with HD Technologies . There are many different types of mills; ball mills, rod mills, SAG (SemiAutogenous Grinding) and autogenous mills In a ball mill, steel or stone balls are mixed with the ore and during rotation of the drum the ore is ground, by friction and compression, into a suitable fineness for the next step in the process The main component of all

SAG mills grinding media includes some large and hard rocks, filled rate of 9% 20%. SAG mill grind ores through impact, attrition, abrasion forces. In practice, for a given ore and equal processing conditions, the AG milling has a finer grind than SAG mills. How does a sag mill work?

But monitoring the condition of a grinding mill is not a trivial task. A SAG mill is a combination of a ball mill and an autogenous mill. mills, a sufficient amount of bigger parts of ore inside the drum is critical to an effective grinding process. Get Price

SKF supplied a customdesigned heavy duty bearing housing assembly and two IMXS conditioning monitoring systems for a 12 MW SAG mill operating on a gold mine in West Africa. This is the first combination online condition monitoring system and drive train solution for a SAG mill supplied by SKF, says project manager, John Storm.

describes the coupling of single vibration sensor data from the CSIRO online monitor to the actual operating conditions of a SAG mill and how the vibration response and hence mill operating conditions vary as a function of time, including during mill equipment failures such as a broken discharge grate.

#0183;#32;This may have been the first hightech condition monitoring tool. NOT! Like Reply. M. Mark Fairbaugh. Apr 10, 2000 #8 We use electronic ears here on Sag mills. The signal is converted to 420 and goes into the PLC and is transfered to the DCS and Expert Control system.

There is strong industry interest in the development of online surface vibration (contact acoustic emission) techniques for monitoring the performance of AG/SAG mills.

With the construction of a new bioproduct pulp mill in Finland, Mets#228; Group selected Valmet DNA Machine Monitoring as an integral part of the millwide Valmet DNA automation system. As part of the machine condition monitoring application, remote diagnostic support provided by Valmet has proved to be an essential aid to predictive maintenance.

Kiln ACD is an effective tool for monitoring the operation of calciners and kilns, and for providing predictive maintenance diagnostics. In particular, Kiln ACD can be used to diag nose product ring plugging, carrying roller alignment, and thrust roller and gearbox load. It is also an ideal tool for condition monitoring.

Metallurgical ContentBall Charge Motion inside a SAG MillSAG Mill OperationSemi Autogenous Design FactorsSAG Mill Operation ExampleProcess Plant DescriptionSAG Mill Design and Specification Operating Problems Since CommissioningDesign Changes and Future Operating Strategies AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the

SAG mills are primarily used at gold, copper and platinum mines where steel balls are used for the grinding. The Manta Controls Advanced Control System, called the SAG Cube, automatically monitors and controls a SAG Mill, keeping track of critical process variables impacting mill throughput.

BrainWave Control solutions for SAG mills540 . Fortunately, with BrainWave monitoring mill load, changes in feed properties are recognized quickly and action is taken before mill loadOptimal operating conditions were better maintained without the risk of mill overload.

SAG Mill Rewedge Work in record time Climax Molybdenum USA Terry Reader, Electr. /Instrumentation Superintendent amp; Norbert van Gorkum, Lifecycle Manager. 1st Long Term Service Agreement 2012 2016 2ndLong Term Service Agreement 2016 2020 #167; Condition Monitoring notifications (CM)

SAG mill feeds. The benefit is that it allows the mill to process a greater throughput of ore than with a typical feed size; however, high throughput means that small changes in ore properties can cause big changes in mill loading to happen very quickly. Fortunately, with BrainWave monitoring mill load, changes in feed properties are recog

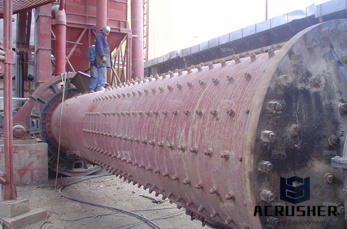

SAG mill lined with 48 rows of HiLow type liners. Because of breakage of Low type Usually by monitoring the wear profile over few liner lives and identifying the areas of and mill operating conditions. Based on the success of the 2D model of the SAG mill,

An Online Surface Vibration Monitoring System for AG/SAG Mills Campbell, Holmes CSIRO Minerals sensitive to various mill operating conditions in a systematic way (Campbell et al

Acoustic emissions monitoring of SAG mill performance Abstract: Particle grinding is a final stage in the comminution process used to liberate minerals from gangue in mineral processing plants. Semiautogenous grinding (SAG) occurs in tumbling mills which

WhatsApp)

WhatsApp)