DicalciumPhosphates Process, Technology, Applications

DicalciumPhosphates Process, Technology, Applications, Patent

WhatsApp)

WhatsApp)

DicalciumPhosphates Process, Technology, Applications, Patent

process for making dicalcium phosphate from rock In Rock based Dicalcium Phosphate manufacturing process industry use many type of raw material in which some are proper quality (rock phosphate, sulphuric acid) and some not at proper remark, these mainly bones or only by product of many inorganic or organic reactions.

Dicalcium phosphate process hydrochloric acid flow phosphate manufacturing process ustng process comprises the reaction of an excess of phosphate rock with aqueous solutions of a mineral acid selected from hydrochloric acid phosphoric acid and nitric acid characterized by the fact that the free acidity of the.

A process for the preparation of feed grade dicalcium phosphate substantially free of fluoride from a source containing monocalcium phosphate such as superphosphate, concentrated super phosphate and fertilizer grade phosphate which comprises the steps of (a) leaching out monocalcium phosphate therefrom with water or recycle wash water from at least one subsequent steps, (b) adding a first

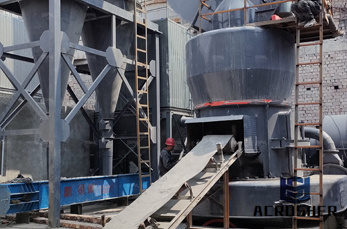

manufacturing process of dicalcium phosphate MC manufacturing process of dicalcium phosphate. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing process of manufacturing calcium phosphatedry process of

This paper presents results laboratory experiments to test a new process for manufacture of dicalcium phosphate. The process is based on the nitric acidulation of phosphate rock concentrate, followed by neutralization of the extract liquor with calcium carbonate. The precipitated dicalcium phosphate is then separated from calcium nitrate solution by filtration.

dicalcium phosphate (DCP), which is a supply of calcium and phosphorus for domestic production process via wet acid digestion; and iii) the accumulation of #187; More detailed What Is Dicalcium Phosphate ? wiseGEEK

Dicalcium phosphate is a crystalline feed grade Dicalcium phosphate containing % Minimum phosphorous and % Maximum calcium. The selected raw material of nonanimal origin and the production process ensures an end product with good phosphorous digestibility and a content of undesirable elements well below that stipulated by EU feed legislation.

The process comprises the reaction of an excess of phosphate rock with aqueous solutions of a mineral acid selected from hydrochloric acid, phosphoric acid and nitric acid, characterized by the fact that the free acidity of the dissolution liquor does not exceed 60% and that in the clear solution feed grade dicalcium phosphate is precipitated with calcium hydroxide, calcium carbonate or mixtures thereof.

This invention relates to the preparation of feed grade dicalcium phosphate from a source containing monocalcium phosphate such as super phosphate, concentrated super phosphate and the like. The first step consists of leaching water soluble mono calcium phosphate therefrom with water or recycle wash water from one of the subsequent steps.

Dicalcium phosphate shows the most commonly used production method is known as the wet acid route in which rock phosphate is reacted with sulphuric acid to produce phosphoric acid. After concentration and purification to reduce the level of undesirable elements, this phosphoric acid is

In a method of making dicalcium phosphate, the steps. which consist intreating phosphate rock with hydrochloric acid under heat, cooling the mixture to about 30 C., treating the liquid product...

Process for the production of dicalcium phosphate The process for producing dicalcium orthophosphate comprising heating monocalcium 30 chlorophosphate, substantially free of calcium chloride, in an atmosphere of steam, at a temperature below the decomposition point of dicalcium orthophosphate and above the vapor condensation point of steam

#0183;#32;Journal of Hazardous Materials 37 (1994) 8389 83 CLEAN PROCESS FOR THE PRODUCTION OF DEFLUORINATED DICALCIUM PHOSPHATE USING PHOSPHATE ROCK M 1 IPT Institute for Technological Research, Chemistry Division, Cidade Universitaria, CEP 05508, Sao Paulo, Brazil Fax 2 UFSCar Federal University of Sao Carlos, Sao Carlos, Brazil ABSTRACT A new process for the production

USA Process for the production of granulated. A process is disclosed for the production of granulated dicalcium phosphate dihydrate from finegrained, powered dicalcium phosphate dihydrate, wherein 80 t0 95% of dicalcium phosphate dihydrate with a grain size of less than 120 m and 20 to 5% of calcium hydroxide with a grain size of less than 120 m are dry mixed and continuously

AllAboutFeed Phosphates it''s all in the chemistry. Dec 01, 2003#183; Unique and efficient process Of its four phosphate production plants in Europe, Tessenderlo Chemie in Ham, northern Belgium, is the biggest, producing more than 50% of the groups total feed phosphate production.

WhatsApp)

WhatsApp)