(PDF) Utilization of EAF Reducing Slag from Stainless

The slag was ground by the vibrating ball mill with the CO 2 and pure water. The reaction behavior was monitored with constant pressure method, and the change of CO 2 volume in the experimental

WhatsApp)

WhatsApp)

The slag was ground by the vibrating ball mill with the CO 2 and pure water. The reaction behavior was monitored with constant pressure method, and the change of CO 2 volume in the experimental

OK cement mill The most energy efficient mill for Proven commercially, the OK mill is the premier roller mill for finish grinding of Portland cement, slag and blended cements. The mill consistently uses five to ten percent less power than other cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is

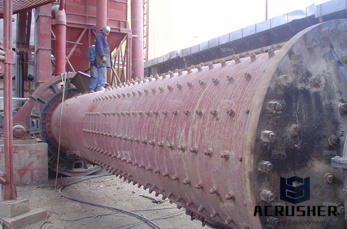

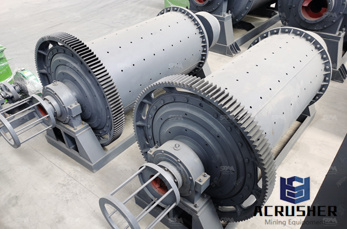

Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding. Large ore outlet and large capacity; The mill with diameter below meters adopts whole machine frame, which is

Energy Saving Ball Mill Introduction: Energysaving ball mill is a high efficient and energy saving ball mill with rolling bearing. Capacity : Up to 160t/h Improvement: Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball

mill consistently uses five to ten percent less power than other. cement vertical roller mills, and in comparison with traditional ball. mill operations, the energy requirements for the OK cement mill is. 3045 percent lower for cement grinding and 4050 percent lower. for slag.

Steel slag ball mill is widely used in cement, silicate, new type building . time,it can grind various ores and other materials in dry type and wet type. . or two paragraph process, and finally get steel slag powder or steel slag fine .

The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time. faster and finer grinding than any other ball mill. speed of 2000 min1 allow for ultrafast pulverization of the sample.

Bulkbuy Whole Plant Energy Saving Limestone Calcination Processing Active Lime Production Line, Active Lime Production Line, Calcining Rotary Kiln price comparison, get China Whole Plant Energy Saving Limestone Calcination Processing Active Lime Production Line, Active Lime Production Line, Calcining Rotary Kiln price comparison from Mini Small Gypsum Incinerator,High Efficient Lime

Oct 23, 2015#0183;#32;Material is fed into the gap between the rolls, and the crushed material leaves as a compacted cake. The energy consumption is kWh/t and about 10 kWh/t when recycling of the material is used. The comminution efficiency of a HPGR is better than ball mills such that it consumes 3050 % of the specific energy as compared to a ball mill.

Steel slag vertical roller millimportant equipment in the steel slag grinding plant As is known to all, in the industrial industry, steel slag is a solid waste that is poorly utilized by steel for extracting some of the metal iron, most of them are not effectively utilized. Most steel plant have not fully utilized steel slag after fully selecting iron.

Our EnergySaving Ball Mill is highly acclaimed for its features of smooth operations, optimum performance, low maintenance and long service life. We offer products include : marble ball mill, calcite ball mill, CaCO3, ball grinder, ball milling machinery, slag ball mill, Sand making machine,drier machine,slag ball mill, ball milling machine

Energysaving ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable materials.

[10/13/2014] Process of Hongrun Steel Slag Mill [09/22/2014] Categories of Magnetic Separator [09/17/2014] Maintenance of Ball Mill [09/15/2014] Ways to Improve Output of Cement Mill [09/11/2014] Energy Saving Ball Mill Improves Reliability of Ball Mill [09/09/2014] Types of Hongrun Tube Ball Mill [09/04/2014] Steel Slag Mill Is Widely Used in

Dry Grinding Coal Ball Clinker Cementslag Supplier Plant Milling Machine Energysaving Cement Mill, Find Complete Details about Dry Grinding Coal Ball Clinker Cementslag Supplier Plant Milling Machine Energysaving Cement Mill,Energysaving Cement Mill,Cement Ball Mill,Grinding Mill from Mine Mill Supplier or ManufacturerZhengzhou Hongji Mining Machinery Co., Ltd.

The crushed raw material, which was cooled in water was prepared for SPS. Raw stainless steel slag (obtained from a steel plant in China, the composition shows in Table 1) was crushed into powder with a particle size lt; obtain a uniform powder of composites, the screened stainless steel slag and chemical reagents (% of purity, 2mm average particle size, produced by Shanghai

energy saving ball mill brand. energy saving gold mining ball mill with iso9001 2 China Energy Saving Wet Gold Grinding Ball Mill China Apr 28 2020 Ball Mill isgenerally used to grind material 14 inch and finer down to the particle size of 20 to 75 microns Ball Milll is an efficient tool for grinding many materials into fine powder The Ball Mill is used to grind many kinds of mine and

The energy saving ball mill is a horizontal rotating device. It has two chambers and is driven by the outer gear. The material is evenly fed into the first chamber throughthe feeding inlet. There is a ladder liner or a ripple liner in the first grinding chamber that contains steel balls of different specifications.

Gold Mine Ball Mill, Ball Nose End Mill, Ball Mill Price manufacturer / supplier in China, offering Energy Saving HighEfficiency Ball Mill for Mine (GMQG1830), Large Capacity Steel Slag Cone Crusher for Iron Ore, Newest Technology Cone Crusher Stone Crusher Price and so on.

Energy Saving Ball Mill Slag mill is mainly used for grinding steel slag,waste residue,mineral waste residue,gypsum,gravel. Related Solutionts *We will provide you with the most suitble producets* Aggregates production line. Mining production line.

Tantalum Extraction With the needs of high technology industry and new technology, niobium, tantalum industry got rapid development. For example, tantalum capacitor can be used in satellite, rocket, missile in electric control system and niobium has become an important raw material of superconducting alloys.

Energy Saving Ball Mill For Stainless Slag. Environmental protection Energysaving Low cost 2019 1 21introduction slag mill is mainly used for grinding steel slagwaste residuemineral waste residuegypsumgravel also can be used for refractory materialfertilizer ferrous and non ferrous metal ore dressing . 2012 energy saving ore slag ball mill

Compared with the traditional ball mill, the energysaving ball mill matches the motor power, saves oil and saves cooling water. Characteristics. 1. Low starting current, short starting time and flexible starting. The normal operating current drops. 2. Reduce the maintenance of the ball bearing main bearing, no oil pollution phenomenon. 3.

WhatsApp)

WhatsApp)