copy milling machine YouTube

#0183;#32;High Speed Wood Copy Milling Machine

WhatsApp)

WhatsApp)

#0183;#32;High Speed Wood Copy Milling Machine

Some milling machines are capable of creating a puzzle effect when several pieces of an object look like theyre trapped within one another and can move a little bit in their cavity. Such an effect is impossible to achieve through metal casting and hard to copy using hand tools.

#0183;#32;A copy milling machine for producing a series of identically shaped wooden products, for instance parts of furniture, starting from mainly identical workpieces, said machine comprising a template, two swingably mounted and rotatably driven milling cutters and two sets of conveyor rollers for passing a template with two adjacent workpieces between both milling cutters, each cutter having two

A copy mill can''t take the place of a drill; the surface area engaged is too large to continue this way much beyond the desired depth of cut for milling. However, the ability to plunge during milling removes a common machining headache: the need to drill a start hole prior to roughing.

With your Tryax milling machine or VMC Digitise and replicate shapes. use your milling machine or router to automatically copy 2D contours and 3D shapes. So to make a decision on which probe that fits your type of work; use the DP4 for...

Primitive flour mills and presses were seen well before the 1600s, proving that milling is an important process to make grains edible for human consumption. Base Center one of the 2by4 pieces of wood on one end of the 4by4 to make a quot;Tquot; and nail it through the 2by4 to the 4by4.

The engraving and copy milling machine according to claim 1, wherein said drive motor means is mounted for driving said tool spindle fixedly on said console carrying said pantograph. 5. The engraving and copy milling machine according to claim 1, wherein said console means is movable by a spindle drive which can selectively be operated manually.

How To Build A CNC Machine. If you have no special tools I am a regular guy. I do not have a huge fancy CNC machine at work. I do not even have a small milling machine or a lathe. My friends do not have them either, so I have nobody to machine some custom parts for me.

Do it yourself guide on how to convert a low cost tower drilling machine into a cool and functional milling machine for prototyping, hobby and fun use :)Fol...

#0183;#32;Several years ago I decided I needed a Milling Machine to replace what I had been using for milling, which was my little drill built it from cannibal...

#0183;#32;Milling machines, like the Bridgeport, Though at the obvious expense of build size. If only the word milling machine were about rigidity in regards to its leverage.

#0183;#32;This video shows the final construction steps of the homemade vertical milling machine. The next video will give you a demonstration and show you everything...

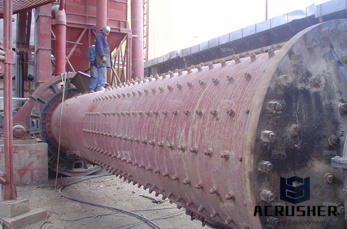

Copy milling machine make ELUMATEC type KF 78; Masch. Nr: 20853 year of construction 1985; Machining size vertical unit: 100 x 290 mm stroke 120 mm; Processing size hor. Unit: 70 x 270 mm stroke 80 mm; Speed of the milling spindle: 12000 rpm; Compressed air connection: 6/8 at#252;; Compressed air requirement: 200 l / min; Span of the profiles: 150 x 150 mm; Drive power: 740 W / 1 HP; Dimensions L

CNC Engraving Machine: CNC Engraving Info for All Writer Bio Le Newman has been a professional writer since 1999, writing about fine arts both in print and online.

A CNC router machine is probably the most useful tool a hobbyist can own, but the price for a CNC machine on the market is way more than the average hobbyist is willing to spend. You can build your own CNC with very basic tools, little knowledge of machinery, mechanics, or electronics, but be warned, these machines are inherently dangerous, so wear the proper protection and use common sense.

When Cody Wilson revealed the worlds first fully 3D printed gun last year, he showed that the maker movement has enabled anyone to create a working, lethal firearm with a click in the

1. Your Rhino designs (2D or 3D) are used by some CAM software (which can run inside Rhino or as an external application) to generate step needs your input to some degree. (This depends on what CAM software you''re using and the complexity of the part.) Generally you need to at least choose a tool or tools, a type of machining strategy to use, feeds and speeds, etc.

While there have been some scratchbuilt CNC Milling machines done, youre best off converting a manual milling machine to CNC until you have a lot of CNC experience under your belt. Therefore, one of the first decisions youll have to make, and one that will determine a lot of other decisions for you down the line, is which manual milling machine to convert.

Drilling a hole for the shaft clamping screw at the end of the arm. This screw will clamp the hole tight, to lock the shaft in place. The screw thread should only engage the bottom half of the arm, so that when the screw is tightened, it pulls the end of the arm together. I''m using a

#0183;#32;Built from Scrap: This CNC Machine Was Made for 160. Donald Bell. I make stuff, play music, and sometimes make stuff that plays music. Fan of donuts, Arduino, BEAM robotics, skateboarding, Buckminster Fuller, Copy Link; Testing the CNC on a sheet of 3mm plastic.

WhatsApp)

WhatsApp)