Making a Ball Mill YouTube

#0183;#32;The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain. Click HERE to subscribe to Make it...

WhatsApp)

WhatsApp)

#0183;#32;The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain. Click HERE to subscribe to Make it...

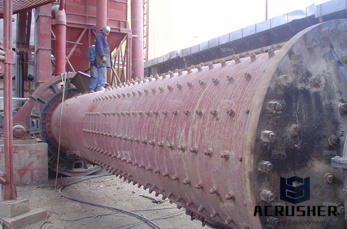

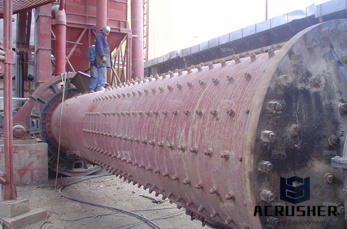

ore process grinding machine ball mill for making. Jan 30, 2017The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder making production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous met Ball mills are also often used on a laboratory scale to process ceramic materials.

Introductions of Ball Mill . General Introduction of Ball Mill: Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the mill.

The Mining Process Waihi Gold. The finer particles receive more grinding in a ball mill, and are size classified to give a final product of 80% more detail on grinding and sizing.

Ball mills grind material by impact and attrition. The degree of milling in a ball mill is influenced by; a. Residence time of the material in the mill chamber. b. The size, density, and number of the balls. c. The nature of the balls (hardness of the grinding material) d. Feed rate and feed level in the vessel.

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

#0183;#32;This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the

How to Make a Ball Mill: 12 Steps (with Pictures) wikiHow

Ball milling is a grinding method that grinds nanotubes into extremely fine powders. During the ball milling process, the collision between the tiny rigid balls in a concealed

the mining process of limeore overflow type ball mill /h3gt; gulin ball mill xa spares suppliers; ore wet ball mill suppliers; ball mills varieties; wet ball . mill process grinding mills machine_corn dry milling/corn dry milling . Ball millWikipedia A ball mill is a type of grinder used tobut it was not until the .

Ball mills/ball mill machine/ball mill grinding description: Ball mills are the key equipment for grinding after the crushing process, which is widely used in the manufacture Favorites Shanghai Clirik Machinery Co., Ltd.

A numerical dynamicmechanical model of a planetary ballmill is developed to study the dependence of process efficiency on milling parameters like ball size and number, jar geometry and velocity

What is a ball mill and how does it function Answers . Ball Mill is widely used in metal and nonmetal mines, building materials and other industrial sectors of crushed materials, and the ball mill is widely used in powdermaking production line including cement,. What is ball milling process? Get Price

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Aug 11, 2007#0183;#32;Make sure to periodically oil everything up. This is a good time to make sure everything is running smoothly. Running a ball mill is quite noisy so it is a good idea to operate it in a closed room or basement. Normal materials will take a couple of hours to mill, but harder things like metals can take days or even weeks so be patient. Uses

Planetary ball mills 9 . Vibration Mills 10 . Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: 8 mm Final fineness: ~ 5 #181;m Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1) process Tip of

Making a Ball Mill: Making a ball mill from a sewing machine motor, a broom stick and some scrap wood. there doesn''t seem to be any proper ball mill instructables on the site, all drill based temporary solutions, so I figured there needed to be one. I''m using 18mm MDF

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles

making a small scale ball mill to grind ore. ball mills iron ore equipment impact crusher machine press Ball Mills In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill amp; ball mills, the ore in order to liberate the minerals In the chemical and process industries

Dec 23, 2020#0183;#32;In an eyeopening recent report it was demonstrated that the ammonia synthesis process could be powered mechanochemically in a simple ball mill laboratory experiment under the seemingly very gentle conditions of 45 #176;C and 1 atmosphere. The mechanochemical ammonia yield reported was found to be significantly higher than the HaberBosch.

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many

#0183;#32;To make a ball mill, start by building a wooden platform and attaching a motor underneath it. Then, cut a slit into the wooden platform for the belt to pass through and attach casters to the platform for the container to sit on.

Nov 14, 2012#0183;#32;PLEASE CONSIDER A DONATION:https://amp;hosted_button_id=RFYRZHKX6464ow to make Black Powder step by step.

Jun 27, 2019#0183;#32;In the production of ethanol, wet ball milling is the process used, because of its versatile process. It produces more products than dry ball milling, but in terms of efficiency, capital, and operating cost, most ethanol plants in the USA prefer to use dry ball milling process. In other words, dry ball milling is cost efficient in ethanol

WhatsApp)

WhatsApp)