Case Study: Cold Rolling Mill Quad Plus

Case Study: Cold Rolling Mill Cold rolling mill needed an update to existing singlepoint measurement system.

WhatsApp)

WhatsApp)

Case Study: Cold Rolling Mill Cold rolling mill needed an update to existing singlepoint measurement system.

A novel customized Cold Rolling Mill designed,supplied amp; commissioned as per customer''s specific DIGI sees itself as an AUTHORITY IN COLD

2 high mill stands (15) Casey has Mill Stands for rolling and producing Blooms, Billets, Bars, Slabs, Plate and Sheet products in either a vertical or horizontal orientation. Contact Casey Equipment for a quote on used 2 high mill stands for sale.

on wear is another issue. Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later. K. H. Schr#246;der July 2003 K. H. Schr#246;der: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS File: SCHROEDER_ROLLS_

Dynamic characteristic analysis of a twostand reversible cold rolling mill in the startup process was carried out. The delay algorithm of the interstand thickness was proposed. A new method combined with the accelerated secant and the tangent methods was established to solve the simultaneous equations. The thickness and interstand tension transition processes with different static tension

Dec 19, 2020#0183;#32;9quot; x 10quot; 2 Hi 1 Stand rolling mill, manual roll adjustment, push button controls, 20 HP D amp; H Machinery Inc, Toledo, OH (Email: sales ) Sales 10quot; x 5quot; Fenn #1214, wire flattening/shaping, 2 stand tandem rolling mill

QMOS Rolling Mill Production module manages the flow of information from the time billets and blooms are charged into the reheat furnace up to the end of the cooling bed. During this process, all process information is gathered and recorded throughout the mill and production and performance metrics are made available in real time.

2 PREFACE _____ Hot and cold metalworking between two or more rolls has been in existence since long before the industrial revolution. As a matter of fact, Leonardo da Vinci was credited for the metalworking mill prior to his death in 1519. When most people think of a rolling mill, they visualize sizable machinery in ferrous (iron, carbon steel

Cold forming Quard 400 is very well suited for cold forming operations. The minimum recommended R/t ratio when bending of Quard 400 is given in the table below: Thickness (mm) Transverse to rolling (R/t) Longitudinal to rolling (R/t) Trans. Width (W/t) Long. Width (W/t) t lt; 8 10 8 t lt; 20 10 10 t 12 12

A twostand reversing cold mill can deliver capacities between 300,000 t/a of thingauge products or 1,000,000 t/a and more of thickergauge products. Main benefits of Primetals Technologies'' reversing cold mills. High production capacity and yield. Flexible, lowcost rolling of a wide range of products, especially for small order lots.

Specifically, in a fivestand tandem cold mill (TCM) in 18HS design, reductions of up to 70 percent are possible. Even a second run of hard material is no problem. Integrated in a TCM, our 18HS allows you to set up a full, continuous production route for stainless steel.

Sep 26, 2020#0183;#32;rolling mill can b e designed as 20 Hi, 12Hi, 8 Hi, 6 Hi, 4 Hi and 2 Hi rolling mills. In India now a days mostly 20 Hi and 4 Hi rolling mills are installed in bi g steel produ ction units.

Tags Rolling Mills; 2High Rolling Mills. Twohigh rolling mills have a unique advantage in cost savings because a 2high configuration is less expensive to manufacture. A 2high mill can be any size. Large rolling mills, similar to photo left, are used for skin passing with small reductions of 1% to 2%.

on wear is another issue. Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later. K. H. Schr#246;der July 2003 K. H. Schr#246;der: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS File: SCHROEDER_ROLLS_

quad engineering : 14quot; (356 mm) dia. quad 2 hi horizontal housingless bar mill stand : 43 horizontal meco : quot; x 43quot; meco two high cold mill stand :

69quot; DavyMcKee Aluminum Cold Rolling Mill: RM442. Manufacturer: Davy McKee Manufacturer DavyMcKee New 1989 Type of Mill: Single stand 4Hi cold mill Hand of mill = right to left Material: Aluminum / 3004 and 5017 alloys Mill Rolling Load Design 1,500 Tons Maximu...

during rolling. After the continuous pickling process, the strip is rinsed, dried, edge trimmed, oiled and rewound into coils. 2 Cold rolling The tandem cold rolling mill takes the pickled hot rolled strip and rolls it to achieve its final thickness of between and mm The tandem mill has several stands equipped with a four high arrangement of rolls.

Cold Rolling Mill Steel strip .Copper strip .Aluminum Strip Input Thickness 26mm Product Thickness : Strip width :mm 4 roller mill,HC mill...

Our solutions cover all types of cold rolling mills for flat products including: 1stand and 2stand Cold reversing Mills, 4high, 6high, 8high and 20high Cluster and Sendzimir Mills, Continuous, Coupled to Pickling Lines and coiltocoil Tandem Mills, 1stand and 2stand Temper Mills.

2 HI 1 Stand Rolling Mill Ref # 10368HK. Click on photo to enlarge2 HI Mill: quot; W x 9quot; Dia. Work Rolls Manual Roll Adjustment Forced Water Cooled Rolls Both Rolls Driven Manual Outboard 43quot; Passline 5quot; x 7quot; Mill Housing Pushbutton Controls 20 HP AC Motor

Tandem cold rolling mills are named by their stand arrangement and designed as sheet mills if they reduce hot band to sheet gauge or tin mills if they roll the same incoming material to tinplate stock. A typical five stand tandem cold rolling mill is illustrated in Figure 1. Figure 1: A typical five stand tandem cold rolling mill

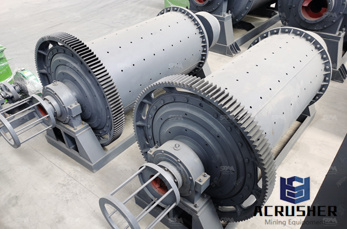

Quard Stand Cold Rolling Mill. Cold Rolling Mill Manufacturer Galvanizing Lines . Yogiji Digi is one of the leading manufacturer and supplier of cold rolling mills, for any query related to our products please call +91 01275 262014 Element has supplied 2 high hot or cold rolling mills designed for specialized separating forces and

Jan 09, 2017#0183;#32;6 HI Cold Rolling Mill 1250 mm 1200 mpm mm Gauge Rolling Duration: 6:40. YOGIJI DIGI 25,841 views. 6:40. How steel is produced Duration: 6:33. worldsteel 999,763 views.

WhatsApp)

WhatsApp)