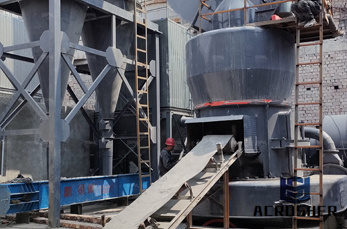

Roller Mill Green Silicon Carbide Production Process

Green silicon carbide Raymond Mill coal crushing plant. Rotary Kiln Rotary Dryer Ball Mill Vertical Roller Mill Raymond Mill High Green silicon carbide Raymond Mill,Ore Crusher,Grinding

WhatsApp)

WhatsApp)

Green silicon carbide Raymond Mill coal crushing plant. Rotary Kiln Rotary Dryer Ball Mill Vertical Roller Mill Raymond Mill High Green silicon carbide Raymond Mill,Ore Crusher,Grinding

PSTEBR2 Small desktop Vertical Electric Two Roll Mill CE Certification. Updated Pro desktop PSTEBR2 is equipped with some special features, including: lighting behind the roller opening, touch screen control and a digital thickness gauge. The machine has forward and reverse speeds for hand use with a safety wire.

Silicon carbide (SiC) is a synthetic, semiconducting fine ceramic that excels in a wide crosssection of industrial markets. Manufacturers benefit from an eclectic offering of silicon carbide grades due to the availability of both highdensity and open porous structures.

For Planetary Ball Mill, Lab Ball Mill, High Energy Ball Mill, Roller Jar Mill, Attritors, Sample Prep Mixer/Mill, Shaker Mill, Mixer Mill, Cryomill, Applications(Use for ) Hard, super hard, abrasive samples, such as hard alloy powder, diamond powder, and silicon carbide powder.

#0183;#32;A rolling mill consists of two steel rollers and you simply pass the metal between the two rollers so that a pattern is made on the surface of the metal. It''s surprising just how effective and fast a rolling mill is at turning plain metal into lovely textured metal, ideal for bracelets, bangles or pendants.

Silicon carbide has been the most widely used material for the use of structural ceramics. Characteristics such as relatively low thermal expansion, high forcetoweight radius, high thermal conductivity, hardness, resistance to abrasion and corrosion, and most importantly, the maintenance of elastic resistance at temperatures up to 1650 #176; C, have led to a wide range of uses.

offers 1,541 silicone roll mill products. About 3% of these are Grinding Equipment, 0% are Rolling Mill, and 10% are Rubber TwoRoll Mills. A wide variety of silicone roll mill options are available to you, such as key selling points, local service location, and applicable industries.

Hubei silicon carbide ultrafine mill is a kind of grinding equipment for grinding silicon carbide into silicon carbide powder. It is mainly used to meet the materials of major industries after silicon carbide processing. Under normal circumstances, silicon carbide can be ground into an arbitrary adjustment within the range of 2500 mesh.

Silicon carbide (SiC), also known as carborundum / k r b r n d m /, is a semiconductor containing silicon and occurs in nature as the extremely rare mineral SiC powder has been massproduced since 1893 for use as an of silicon carbide can be bonded together by sintering to form very hard ceramics that are widely used in applications

silicon carbide roller bonded silicon carbide rollor: it is used for polishing, removing dust amp; removing seed coat from mong, urad, barley, mayar, wheat, arhar, gram, kodri etc. particulars for bonded emery silicon carbide roller. s. No. size in inch.

HGT Gyratory Crusher. YGM75 high pressure mill ready for deliveryJoyal Crusher. Vertical roller mill grinding machine to improve the Vertical roller mill grinding machine to improve the utilization of silicon carbide Main use of silicon carbide for 312 inch single crystal silicon polysilicon potassium arsenide quartz crystal and other wire cutting Solar photovoltaic industry semiconductor

Eemco Two Roll Mill 6 X 13 Two Roll #16530. Manufacturer: Eemco Two Roll Mill Two roll rubber mill by eemco (erie engineering and manufacturing co.), serial # 651005. Features stainless steel 6quot; diameter x 13quot; long roll s, 7. 5 horsepower motor and gear reducer, 208230/460/3 phase voltage...

Professional manufacturer of Tungsten carbide roll ring and guide rollers for steel, copper, aluminium and wire industrial Skip to content Call Us Today! +86 731 | sales

Silicon carbide mill requires high standard for grinding ability and output, Guilin Hong Cheng launches a type of silicon carbide mill which has the following advantages: integration of grinding amp;conveying; one button automatic starting up; some key parts (such as roller)made from high quality and thickened steel contribute to the improvement of abrasive resistance and rust resistance of the

Washington Mills is an expert at manufacturing silicon carbide grains and powders. Our CARBOREX grains and powders are made to your exact size, chemistry, and shape specification. We control the manufacturing process for silicon carbide offering a unique ability to customize materials to your toughest specification.

For example, the weight of a 500ml carbide grinding jar is about, we recommend to use in 4L planetary ball mill instead of 2L planetary ball mill, otherwise it is overloaded. Backed by our longstanding commitment to customer satisfaction, we ensure quality manufacturing and reliable supply of tungsten carbide grinding tools to meet your most demanding requirements for sample preparation.

two roller mill for silicon carbide . two roller mill for silicon carbide; 20 Dec. Approved Vendors List Welcome to 3E Technology, Inc. 3E Technology, Inc. Part Number amp; Description List: (Partial List, More than 400kb) Please note that some of the lists are quite long! Please select company by clicking on one of the characters. Chat Now

#0183;#32;After being ground by a vertical roller mill, silicon carbide is used in many applications, namely: functional ceramics, advanced refractory materials, abrasives and metallurgical raw materials. At present, the raw material of silicon carbide can be supplied in large quantities, which cannot be regarded as hightech products, and the technical content is extremely high.

Silicon Carbide | Washington Mills

WhatsApp)

WhatsApp)