Coal and Ash Handling SlideShare

#0183;#32;COAL PREPARATION PLANT 24VANITA THAKKAR BIT, VARNAMA TYPICAL FLOW PROBLEMS IN BINS 58VANITA THAKKAR BIT, VARNAMA High power consumption when fine coal is require. Limited capacity. Metal scrap cannot be

WhatsApp)

WhatsApp)

#0183;#32;COAL PREPARATION PLANT 24VANITA THAKKAR BIT, VARNAMA TYPICAL FLOW PROBLEMS IN BINS 58VANITA THAKKAR BIT, VARNAMA High power consumption when fine coal is require. Limited capacity. Metal scrap cannot be

IEA Clean Coal Centre Operating ratio and cost of coal power generation 8 List of Figures Figure 1 Primary energy consumption for the G20 countries in 2000 and 2015 11 Figure 2 The distribution of power generation by fuel in 2000 and 2015 in the G20 countries 12 Figure 3 Trends in coal consumption in the G20 countries, %/y 12

Production Consumption FIGURE 72. Coal production and consumption in the in the past 150 years. [Source: Energy Information Administration.] Coal Formation As described in the general discussion of the carbon cycle (Chapter 6), coal was formed from prehistoric plants, in marshy environments, some tens or hundreds of millions of years ago.

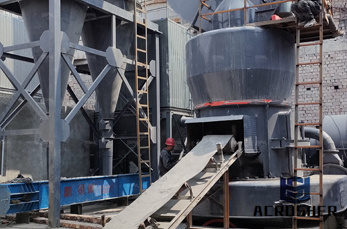

A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

Electric power consumption (kWh per capita) from The World Bank: Data Learn how the World Bank Group is helping countries with COVID19 (coronavirus). Find Out

commercial power Typical Emissions using washed coal (30%) in a standard Indian coalfired power plant Carbon Dioxide kilograms carbon dioxide per kilo watt hour commercial power Other Cobenefits: Reduction in auxiliary power consumption, reduction in flyash management costs at power plants, lowered ESP

The basic function of the power plant is to convert energy in coal to electricity. Therefore, the first thing we should know is how much energy there is in coal. Energy content of coal is given in terms of KiloJoules (kJ) per Kilogram (kg) of coal as the Gross calorific value (GCV) or the Higher Heating value (HHV) of coal. This value can vary

May 29, 2020#0183;#32; coal consumption decreased % from the 2018 level to MMst. The electric power sector accounted for about % of the total coal consumed in 2019. The average sales price of bituminous coal was per short ton, a % decrease from the 2018 level.

Food preparation 35% Lighting 13% Energy Consumption In Breweries (All Sizes) Data from the Environmental Protection Agency (EPA) show that refrigeration, packaging and compressed aire consume 70% of breweries electricity use (A), whereas the brewhouse dominates natural gas and coal use at 45 percent (B). Energy Consumption Within

Sep 03, 2020#0183;#32;Growth in coal consumption by electric power sector coal companies by capacity of retirements capacity of coal facility retirements

Coal preparation plant process and equipment for coal Mar 27, 2019 Taking a coal washing plant in Indonesia as an example, the coking coal preparation plant with an annual processing capacity of 4 million tons can increase the processing capacity per hour to more than 700 tons, and the power consumption, media consumption, fuel consumption, and water consumption are all reduced.

Dec 23, 2020#0183;#32;Power sector consumed 30% less coal in firsthalf 2020 than in firsthalf 2019 tags: consumption/demand electricity generation More coal was consumed in Indiana than in

NOT valid for estimation of H if coal shipments are a blend of low rank coal, or anthracite, or petcoke, and bituminous coals Note 4. NOT valid for low rank coal, anthracite, petcoke, or coke ISO 1928 2009 Part wH = x w(V) + x qv,gr,m x [ 100 M T w(A) ]

Nov 22, 2017#0183;#32;Like nuclear, our estimates of daily electrical output from coalfired power stations have been calculated based on reported maximum capacity figures, found here, and an average capacity factor of 64%. 4 The largest operating coal plant in the world is the Tiachung Power Plant in Taiwan; with a maximum capacity of 5500 MW, average daily output would be approximately 85,000 MWh (5,500MW

Coal Handling System Linkedin Slideshare. Coal handling system saif coal handling system by shaikh saif of coal handling system a 600mw power plant handles about 7200 tons of coals per handlings are to be flexible, reliable capable of handling large quantities in less time than even plays a vital role in electricity generation

Indiana Center for Coal Technology Research 1 Brian H. Bowen, Marty W. Irwin electric power generation in the It has a higher heating value than either Indiana Center for Coal Technology Research 13 COAL TYPICAL CONTENT % weight Anthracite

#0183;#32;The Coal Generator is a building that generates Power using Coal and Water. It is the first fully automateable power source the engineer has access to and also the first power source to use a mined resource. 1 Fuel consumption 2 Generators per Coal node 3 Generators fueled by Compacted Coal 4 Generators fueled by Petroleum Coke 5 Overclocking the generator 6 Coal power setup

After considering the conversion efficiency in a power plant we require an heat input of (3600 / % ) 10765 kJ/ kw hr. Coal Quantity. Since coal has a heat value of 20,000 kJ/kg, for producing one we require (10765 / 20000) kg of coal. This translates to ( x 100 x 1,000) 53800 kg/hr ( T/hr) of coal for an output of 100 MW.

What Is Coal Preparation? Energy Typical Emissions using raw coal (42%) in a standard Indian coal fired power plant. Carbon Dioxide kilograms carbon

typical power consumption coal preparation. Gulin machine in iron ore processing plant, typical power consumption coal provide the typical power consumption coal preparation

WhatsApp)

WhatsApp)