Waste Tyre Pyrolysis Carbon Black Processing Machine,

Waste Tyre Pyrolysis Carbon Black Processing Machine, US 5000 200000 / Set, New, micro powder grinding mill, AC from Shanghai Clirik Machinery Co., Ltd. on

WhatsApp)

WhatsApp)

Waste Tyre Pyrolysis Carbon Black Processing Machine, US 5000 200000 / Set, New, micro powder grinding mill, AC from Shanghai Clirik Machinery Co., Ltd. on

HGM series carbon black grinding milladopts GCr15SiMn for Ring and Roller, which is better than normal 60Si2Mn. So far, it is good at waste tyre pyrolysis carbon black micron powder making. Shanghai Clirik Machinery devoted to provide carbon black processing and

One way is to incinerate the tires to produce energy, which is not a sustainable future solution as the resources are lost. A second way is Pyrolysis, which generates oil, gas, steel and recovered Carbon Black (rCB) as final products. Especially the rCB can be used to replace the Carbon Black in various applications.

In recent years, waste tyre/tire pyrolysis has proven to be an effective thermochemical process for the recycling of waste tires. Waste tyre/tire pyrolysis as one important of pyrolysis carbon black processing machine, after pyrolysis, three fractions are obtained: carbonaceous solids, liquid hydrocarbons, and the socalled noncondensable gases.. The pyrolysis reactor outlet provides a gas

Shanghai Clirik Machinery has been in this field over 10 years, designed and produced a vertical roller mill, which are best for carbon black micro powder processing. Please see below standard carbon black processing plant, and wed like to introduce the workflow: waste type pyrolysis carbon black processing system After pyrolysis, CB is a

Carbon Black Produced From Tyre Pyrolysis Plant. 20 Jan 2015 The coarse carbon black from waste tyre pyrolysis is about 5060 mesh. The Carbon Black Processing Machine in pyrolysis industry: It can be used for grinding barite, limestone, porcelain, slag and other materials that. High yield and simple onestep production of carbon black

Condition: New Certification: ISO, CE Automation: Automatic Treatment: Pyrolysis Name: New Design High Quality Batch/Intermittent Equipme Advantage: High Efficiency

Carbon Black from Tyre Pyrolysis Beston Machinery. When waste tyres are transformed by pyrolysis, the obtained solid fraction known as pyrolytic carbon black (CBp) contains the original CB (8090 wt.%) added in tyre manufacturing process along

Generally speaking, we get carbon black from tyre pyrolysis or waste plastics is about 5060 mesh, which is also called coarse carbon black. So we so we need to further processing these coarse carbon black. Beston carbon black processing machine can

In order to further process the carbon black from tyre pyrolysis process, we have developed the carbon black processing plant (also called carbon black grinding machine), which takes advantage of the reversibility of waste rubber tires (polymer raw materials). It can not only beneficial for the society, but also create greater economic benefits.

Plant directly supply carbon black processing machine. US 700850 / Metric Ton. Waste Tyre Pyrolysis Plant Tire Pyrolysis Machine Offers. Waste tyre pyrolysis plant from Beston can process 6 to 24 tons per day, including Reprocessed into quality carbon by carbon black grinding equipment 3. When we use waste pyrolysis machine to extract oil from

If you are investing in the carbon black processing machine, or you want to get the carbon black from tyre pyrolysis or plastic pyrolysis, please dont hesitate to contact us. And we will give you a free quote online. Our carbon black processing machine mainly

In this way carbon black processing machine is a kind of environmental equipment for getting carbon black from tyre pyrolysis. The carbon black can be used for construction bricks with clay, also can be used as fuel. BMF10 Carbon Black Processing Machine. Get Free Quote in 24 Hours

Carbon Black Processing Plant. Beston carbon black processing plant is used for deep processing carbon black from waste tyre/plastic/rubber pyrolysis, biomass garbage, construction material grinding and so on. The plant is also called carbon black grinding machine, which refers to making carbon black characterized as N220, N330,N660, etc.

Use of waste tyres . Waste tyres after pyrolysis, we can get metal parts, heavy crude oil, gas and carbon black. Metal and gas can be recycled. Crude oil can be distilled into fuel oil. Carbon black can be further processed into different sizes, and broadly used in rubber and painting industry. The specific usages are as followed:

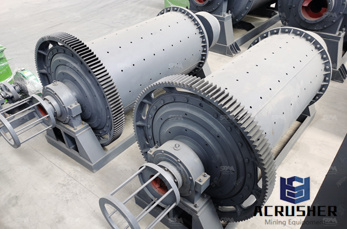

Carbon black processing plant / waste tyre pyrolysis carbon black processing plant, US 15000 65000 / Set, New, Ball Mill, grinding mill, AC from Gongyi City Songling Tengda Machinery Factory on

In recent years, waste tyre/tire pyrolysis has proven to be an effective thermochemical process for the recycling of waste tires. Waste tyre/tire pyrolysis as one important of pyrolysis carbon black processing machine, after pyrolysis, three fractions are obtained: carbonaceous solids, liquid hydrocarbons, and the socalled noncondensable gases.. The pyrolysis reactor outlet provides a gas

The carbon black from tyre pyrolysis uses add higher added values into the pyrolysis equipment, which makes the equipment more profitable and beneficial. Moreover, the other end products, both tire pyrolysis oil and steel wire also have various applications, which can bring you endless profits. To get more highquality carbon black from waste tyre pyrolysis and make great profits from this project, we should

WhatsApp)

WhatsApp)