Difference Between Wet And Dry Process Of Cement

8 #0183;#32;Nov 06, 2019#0183;#32;There are two different processes for manufacturing cement. wet process minerals are wet

WhatsApp)

WhatsApp)

8 #0183;#32;Nov 06, 2019#0183;#32;There are two different processes for manufacturing cement. wet process minerals are wet

Fig: Manufacture of Cement by Dry Process. b) Wet Process. The raw materials are firstly crushed and made into powdered form and stored in silos. The clay is then washed in washing mills to remove adhering organic matters found in clay.

Follow us: https:// more information:: +91, ...

The cement manufacturing is done by majorly by two methods known as wet process and dry process depending on their mixing is done with water or without water. The wet process of cement manufacturing too popular for several decades because of the possibility of more accurate control while raw material mixing.

manufacturing of cement. In cement: Manufacture of cement. manufacture are known as the wet, dry, and semidry processes and are so termed when the raw materials are ground wet and fed to the kiln as a slurry, ground dry and fed as a dry powder, or ground dry and then moistened to form nodules that are fed to. Read More.

Jul 09, 2020#0183;#32;Jul 9, 2020 cement manufacturing process, cement production process, clinker, flow diagram of cement production, manufacturing process of cement by wet process, preheating tower Cement is the most significant material used in construction and

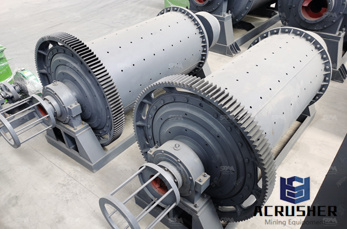

Dec 07, 2020#0183;#32;Grinding is the next step in the cement manufacturing process, and it can occur in either wet or dry forms. Wet grinding involves combining all of the materials in a mill with water and grinding it into slurry. In contrast, dry grinding processes combine and grind the materials without water, creating a substance known as kiln feed.

Mar 28, 2018#0183;#32;Wet process Mixing of Raw materials in wash mill with 35 to 50% water. Materials exiting the

Wet and semiwet process cement kilns. Clays in general are both hydrophilic and fine, and clays milled alone produce pumpable slurries with 6070% water content, although some comparatively rare quot;swellingquot; clays require much more water: a bentonite clay paste with 95% water is practically solid.

Wet Process of Cement Manufacturing Cement Wet Process amp; Cemen

it is finely broken up and dispersed in water in a washmill. The clay. is also broken up and mixed with water, usually in a similar washmill. The two mixtures are now pumped so as to mix in predetermined proportions and pass through a series of screens. The resulting

In the wet process, first of all, the newly quarried limestone is crushed into smaller pieces. Then in the ball or tube mill, it is mixed with clay or shale with water to form a slurry. The slurry is a liquid of creamy consistency with a water content of about 35 to 50 percent, wherein particles, crushed to the fineness are held in suspension.

Portland cement is two processes, known as wet or dry processes depending upon whether the mixing and grinding of materials done in wet or dry conditions. A wet process was popular in the early years because of the possibility of more accurate control in the mixing of raw materials.

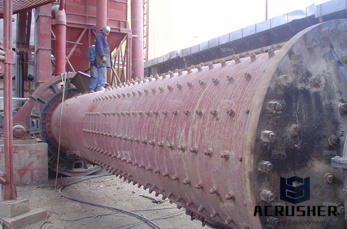

Jun 21, 2016#0183;#32;The kiln has to operate continuously in order to ensure a steady regime, and therefore uniformity of clinker. The larger existing kiln in a wet process plant produces 3600 tonnes of clinker per day. The manufacture of cement by wet process is energy intensive and thus uneconomical as compared to dry process and semi dry process.

Apr 05, 2020#0183;#32;Wet process of cement manufacturing (Flow chart) The length of the rotary kiln may vary anything from 30 meters to 200 meters. The slurry on being sprayed against a hot surface of a flexible chain loses moisture and becomes flakes.

Water use and discharge in cement production. Water is used in cement production to suppress dust, to condition or cool kiln exhaust gases, to finish mills, and for noncontact cooling. About 1 tonne of water is discharged in the production of 1 tonne of cement.

Aug 17, 1971#0183;#32;Classification Code (SCC) for portland cement plants with wet process kilns is 305006, and the sixdigit SCC for plants with dry process kilns is 305007. Portland cement accounts for 95 percent of the hydraulic cement production in the United States. The balance of domestic cement production is primarily masonry cement. Both of these

Here is the manufacturing of cement by wet process. WET PROCESS. When the raw materials are soft, then the wet process is preferable to be used. The cement is manufactured by the following procedure:Mixing of Raw Materials: In the wet process, there are two raw materials e. calcareous and argillaceous.

Manufacturing the cement kiln Wet process kilns. The original rotary cement kilns were called ''wet process'' kilns. In their basic form they were... Dry process kilns. In a modern works, the blended raw material enters the kiln via the preheater tower. Here, hot gases... The clinker cooler. There

Dec 13, 2018#0183;#32;The wet process, on the other hand, is free from the dust, grinding is easier and the composition of the cement can easily be controlled. Wet Process The specific feature of the wet process is that the raw materials are prepared in water whereas in the

Apr 20, 2019#0183;#32;The wet process of cement manufacturing refers to grinding raw material into slurry after mixing with water and then feeding them into the wet process kiln for drying and calcination and finally forming clinker. The slurrys water content is usually between 32%36%.

Wet process kilns. The original rotary cement kilns were called ''wet process'' kilns. In their basic form they were relatively simple compared with modern developments. The raw meal was supplied at ambient temperature in the form of a slurry. A wet process kiln may be up to 200m long and 6m in diameter.

WhatsApp)

WhatsApp)