Contamination from Zirconia ball during milling process.

I have done the milling process for an Alumina sample using zirconia ball. However from EDX and XRD analysis it is showing very high contamination of Zirconia element.

WhatsApp)

WhatsApp)

I have done the milling process for an Alumina sample using zirconia ball. However from EDX and XRD analysis it is showing very high contamination of Zirconia element.

During milling of powder in planetary ball mill (WCvial with WC grinding media), the powder becomes contaminated with carbon. So how can we remove this carbon from milled powder? View

Grinding Zircon Ball. BAOSHISHAN 1000g Zirconia Grinding Balls 10mm Zirconium Oxide Beads Ultrafine for Lab Planetary Ball Mill 10mm out of 5 stars 1. Only 6 left in stock order soon. Aquatic Arts FilterPlus BioMedia Aquarium Filter out of 5 stars 139. Only 4 left in stock order soon. Get Price List Chat Online

New: Silicon Carbide (SiC) Grinding Balls and Silicon Nitride (Si3N4) Grinding Balls Ball mill grinding media and milling media are used in milling or grinding processes to crush, grind and mill various materials. MSE Supplies offers a wide variety of grinding media and ball milling media with the package size ranging from kg and tons.

Zirconia Balls For Ball Mill. Features: Zirconia ceramics, ZrO2 Ceramics and zirconia ceramics have excellent properties such as high melting point and boiling point, high hardness, insulator at room temperature, and conductivity at high temperature. Applications: 1. 1. It is applied to the grinding of some samples with high hardness; 2. It is used in grinding with high requirements and purity;

4. Low using cost: Zirconia ball saves your costs greatly, such as reducing media and equipment abrasion, saving electricity and labor cost and so on. Applications: Zircoia mill ball is used for grinding materials into ultrafine powder in wet and dry methods. It is commonly applied to the following fields:

New: Silicon Carbide (SiC) Grinding Balls and Silicon Nitride (Si3N4) Grinding Balls Ball mill grinding media and milling media are used in milling or grinding processes to crush, grind and mill various materials. MSE Supplies offers a wide variety of grinding media and ball milling media with the package size ranging from kg and tons.

Semi Circle Planetary Ball Milling Machine With High Purity Zirconia Ball Mill Jar; 50ml To 20l Ball Mill Jar With Stainless Steel Balls Corrosion Resistance; Stainless Steel Ball Mill, 360#176; Turning Rotary Ball Mill Machine 2L; Super Fine Powder Lab Ball Mill Machine With 360 Full

Zirconia (YSZ) grinding media is the most durable and efficient media for ball milling and attrition milling of ceramic materials. Zirconia grinding media provides a virtually contaminationfree ball milling solution for a variety of industries.

Yttriumstabilized zirconia grinding media is used to make a zirconia ball. It is a longlasting and contaminationfree finishing media. It is the best tumbling media for ball milling and attrition milling applications, especially for ceramic materials. It is also suitable for the wet grinding process in highvelocity conditions.

Zirconia Ball Mill Grinding Media With High Quality Mixing Grinding Laboratory Ball Mills 4l Polyurethane Jars, Find Complete Details about Zirconia Ball Mill Grinding Media With High Quality Mixing Grinding Laboratory Ball Mills 4l Polyurethane Jars,Ball Mill Media,Grinding Ball Mill Media,Zirconia Grinding Ball Mill Machine from Ceramics Supplier or ManufacturerChangsha

Zirconia (YSZ) grinding media is the most durable and efficient media for ball milling and attrition milling of ceramic materials. Zirconia grinding media provides a virtually contaminationfree ball milling solution for a variety of industries. SPHERICAL ZIRCONIA (YSZ) GRINDING MEDIA,, mm 1mm, mm,2 mm,3mm, 5mm,,10mm,12mm,

#0183;#32;Attrition mills rotate the stirrer to lead the movement of the grinding balls. Conventional ball mills are usually used in conjunction with chemical treatments due to their low efficiency (Zhao et al., 2006). Planetary and attrition mills are effective in fermentable sugar production (Kim et al., 2013).

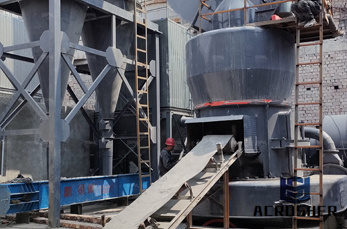

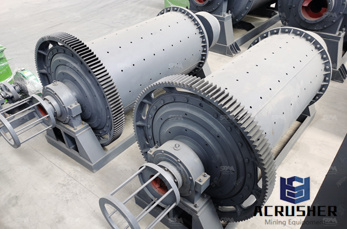

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

offers 1,585 zirconia ball mill grinding media products. About 38% of these are Ceramics. A wide variety of zirconia ball mill grinding media options are available to you, such as application.

With over 20 years development, Inovatec aims to help improve our clients grinding and milling productivity and reduce operational cost. We are not only supply the zirconia grinding media, but also a complete ball includes Yttria Stablized Zirconia beads, Ceria Stablized Zirconia beads, Aluminum toughened zirconia ball and zirconia silicate beads.

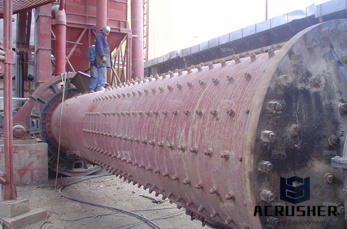

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 2040% water by weight.

Silicon Carbide Balls are very highcost grinding media that are used for milling same materials (silicon carbide ball to mill silicon carbide materials) to avoid contamination. They are only available in 5mm,10mm, 15mm and 20mm sizes. They are a special order item.

WhatsApp)

WhatsApp)